In the 1850s, the men and women of Natick were making nearly 1,300,000 pairs of shoes and boots each year.

The Natick Shoe Industry

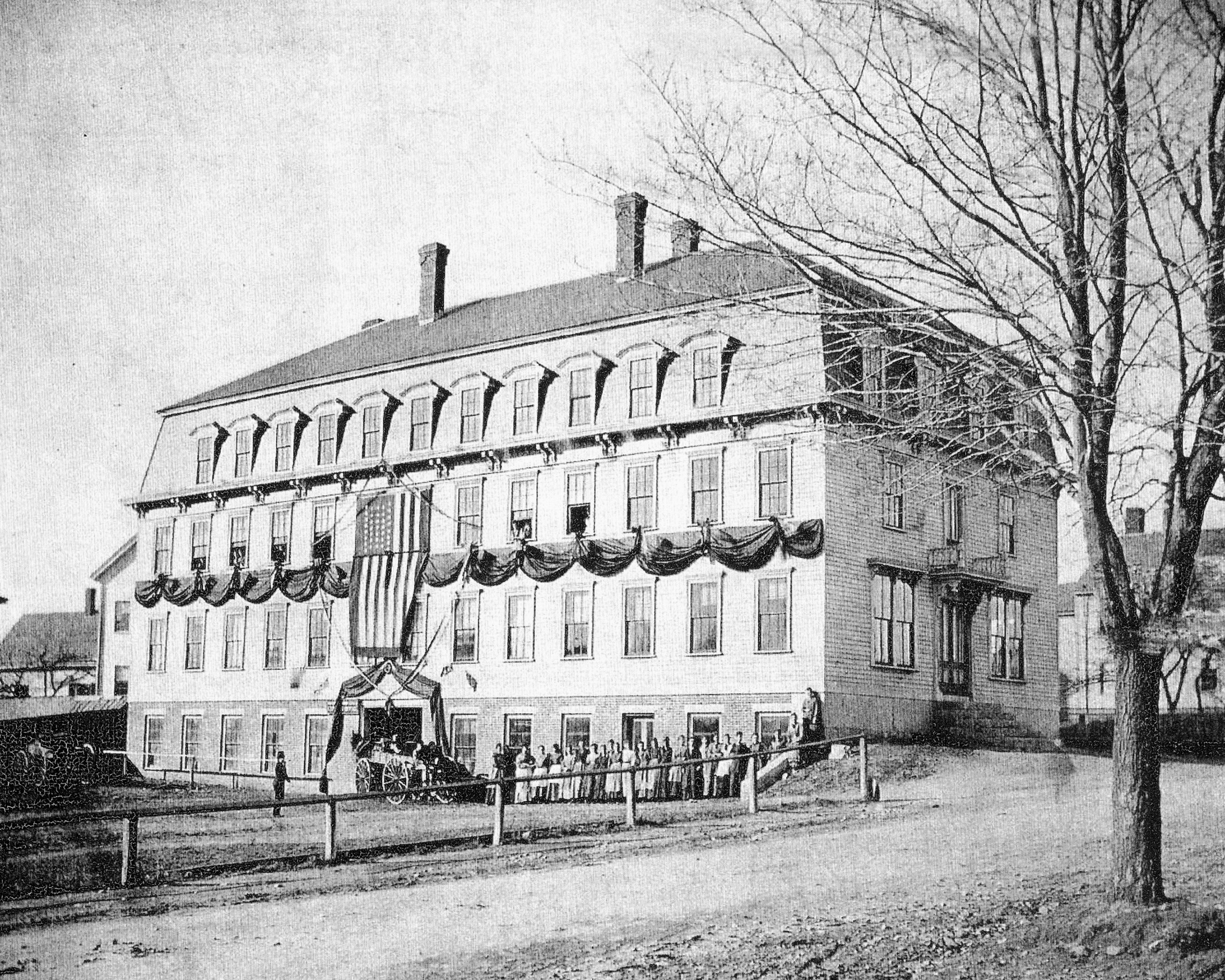

In 1830, Natick was a quiet agricultural community of 900 residents, nearly all of whom weren’t making shoes. Within 25 years, the town was a bustling shoe manufacturing center, with more than 7,500 men and women at work making brogans and other shoes for sale throughout the country.

Like other towns nearby, Natick had local shoemakers who produced and repaired shoes for friends and neighbors in their community. When Andrew Jackson was elected president (1828), Edward Walcott of West Natick began to make more boots than the townsfolk needed, so he started to develop markets elsewhere. This helped mark the beginning of Natick’s shoe industry. By the 1830s, more men joined Walcott in cutting and assembling the primitive work shoes called brogans and sending them to Boston for sale. Horse-drawn wagons transported shoes to the city weekly, and on the return trip, the wagons carried more leather to make more shoes.

Henry Wilson’s ten-footer, is still visible on West Central Street in Natick.

Traditionally, shoes were made by hand, and one man usually did all the work on a shoe. Nearly every home in Natick had a small workshop for shoemaking in its backyard or attached to the home. These shacks were between 10 and 14 feet on a side—commonly called “ten-footers”—and contained four to eight work benches. These ten-footers appeared throughout Massachusetts as one town after another became active in the shoe marketplace.

As the market grew for the kind of work shoes made in Natick—primarily in the South and in the West Indies for use by enslaved people and in the West for miners—the production method changed dramatically. Men with an entrepreneurial bent who wanted to run a business rather than work the trade bought bigger buildings that could hold more benches, better tools, and machinery being developed to take over some of the manual labor. Instead of each man constructing the whole shoe, each man became an expert in a part of the process. Eventually, one workman would make the parts, and more skilled workmen would finish the shoes. Shoe manufacturing provided a career pathway for the self-made man who could begin at the bottom—maybe by working in a ten-footer—then proceed to a factory where he could improve his skill. Later, perhaps, if he saved his money, he could open his shop.

Even as the number of factories grew, the ten-footers remained in business—laborers could still work at home doing piece work to prepare the shoe parts. Women started to earn money as piece workers. Factory cuttings were delivered to the shacks throughout the town, where the workers would put the shoes together and then send them back to the factory to be finished and packed for delivery.

From 1850 to 1864, women hand-sewed the shoes and bound the edges in their homes or ten-footer shops. This was called “closing the shoes.” During the Civil War, women could support their families this way while their husbands served their country. Later, much of the stitching was done in a specialty shop owned by W. C. Childs in an alley in the town center behind the Masonic Block.

Shoemakers were called cordwainers and earned good money—wages were relatively high, and living expenses were low. A good workman, during factory hours—7 a.m. to noon and 1 p.m. to 6 p.m., could earn $6 or $7 per day. If a man worked by the piece, he could earn even more. A good boot treer (the shaping of a boot was called treeing) could earn $8 to $10 in six or seven hours. Henry Thompson, a first-class Natick boot treer, earned $10 daily and left work by 3 p.m.

The Pfeiffer Shoe factory on Water Street - the last shop in South Natick (it closed during the 1930s Depression).

The wooden peg (“pick”) for uniting the sole and the upper was invented in 1818 by Joseph Walker of Hopkinton. It was very crude—the picks were hand-driven—but it was a beginning. A new pegging machine in general use by 1858 could peg two pairs of women’s shoes per minute. In 1858, the McKay Sewing Machine was invented. This machine could sew 100 pairs of shoes in an hour. The pegging and sewing machines radically sped up the manufacture of shoes. The added productivity expanded production capacity and increased the number of workers in the local industry.

Other machines, all American inventions, also improved shoe production. In 1885, a machine that could finish 75 shoes in a 10-hour day (a skilled man, working by hand, could turn out 50 shoes) was invented by Jan Matzeliger, a man from Dutch Guinea with little schooling and poor English who had settled in Lynn. An improved machine version soon produced 700 shoes daily, further revolutionizing the shoe-making industry.

Natick shoe production in 1855 was reported to be 1,281,295 pairs valued at $1,163,808, with 7,070 men and 497 women employed in the shoe factories. In the latter part of the 19th century, shoe-making was the principal business in town. A shoe factory owner was an easily recognized and respected citizen as he made his way through his black clothes, and the town was wearing a derby hat, yellow kid gloves, and yellow shoes. He grandly drove a horse and two-seater buggy. Lynn was the first town in Massachusetts to manufacture shoes—Lynn’s specialty was women’s footwear—and Lynn and other towns across the state have similar stories of growth based on shoe production.

The Boston Globe of June 20, 1885, cited 23 cities and towns that produced shoes. Each town generated a business of over a million dollars annually. The top 10 were:

Lynn $20,946,867

Haverhill $10,557,364

Brockton $ 7,411,919

Marlboro $ 5,169,356

Worcester $ 4,703,705

Weymouth $ 3,514,434

Natick $ 3,062,509

Boston $ 2,670,823

Beverly $ 2,483,831

Spencer $ 2,347,000

G.A. Peterson repair shop north of Natick’s town center.

As the shoe industry grew, it developed the need for lasts (which shaped the shoes) and wooden boxes to support the manufacturing and shipping operations. Box and last factories were established, and stitching and transport companies grew, employing numerous support workers.

How many shoe factories did Natick have? A definitive answer to that question has eluded researchers so far, but the Society has identified 67 names of shoe companies, including large and small operations. Many of these companies operated successively over time in the same buildings. We do know that Edward Walcott’s operation was the earliest, established in 1828. The Pfeiffer Shoe factory on Water Street was the last shoe operation in South Natick before it closed during the 1930s Depression. The Winchell Shoe Company on Washington Avenue was the last of Natick’s shoe firms, and it closed in 1971.