The first baseball factory in America was built on Walnut Street in 1858 by Harrison Harwood.

Natick’s Harwood Baseball Factory

While walking past or waiting at the Natick Center train station, look at the giant “Natick Harwood Baseball” on the great mural that faces the inbound passenger platform. The date on the ball hints at when baseball history was being made just a block north of the tracks. Harrison Harwood chose that site, at Walnut Street and North Avenue, to build the first baseball factory in America in 1858.

Baseballs and bats (almost a dozen different styles) from H. Harwood and Sons were used throughout the United States and Canada. In 1871, the factory was busy, producing about 30,000 dozen balls in Natick. An 1871 receipt reflects the variety of balls and bats produced in Natick. By 1891, the cost of a baseball ranged from just a nickel to $1.25.

“Lemon-peel” or “figure-eight”?

In the early days of the new American sport, baseballs typically had a core (such as a small rock) wrapped with yarn and covered in leather or sheepskin, stitching around the circumference described as the “lemon-peel” style. These early baseballs were lighter and softer than the modern ball, designed to suit the play action among the early teams. By the mid-1840s, the rules of organized play changed to require a harder baseball that better matched the changing style of the game, and baseball construction was switching to a ball with a rubber core covered with yarn and leather. In the 1800s, baseballs varied in size and weight until, in 1872, the National Association of Baseball Players required a ball to weigh 5 - 5 ¼ ounces, with a circumference of about 9 - 9 ¼ inches. Essentially, those specifications are still in force today in major league baseball.

Two Natick residents, John W. Walcott and Col. William A. Cutler, who played baseball, pioneered modern baseball design. Both men were active in the shoemaking industry and were familiar with handling and working leather into rounded shapes. Mr. Walcott advanced the yarn-wound core idea, resulting in a more resilient “active” ball. Col. Cutler reportedly worked in the kitchen of his home at 10 West Central Street and came up with the “figure-eight” cover design and stitching that was a significant improvement in the 19th century and is readily familiar today. Col. Cutler then sold his design to Harrison Harwood Sr.

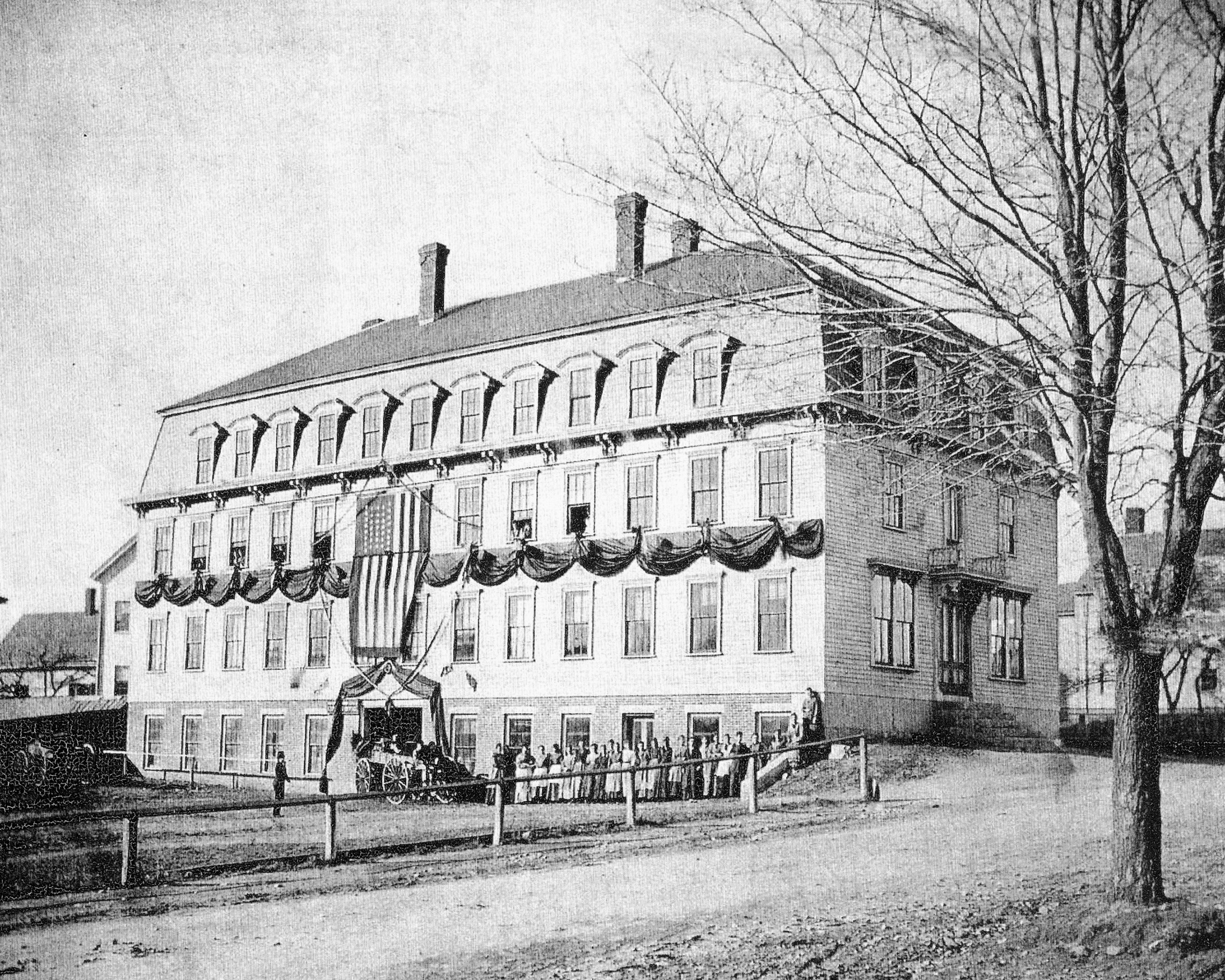

The Harwood baseball factory

In 1858, Mr. Harrison Harwood Sr. set up his factory—H. Harwood & Sons—in the center of Natick to manufacture Official League Baseballs. In the first year of production, he recorded $150,000 in sales. The highest quality balls were covered with horsehide, and sheepskin was used for the cheaper balls. The best balls were stitched with silk thread, and linen thread was used for the others. A "cottage industry” was built among Natick women who stitched balls at home. Wagon drivers would deliver piecework and subsequently collect the balls for factory finishing. Baseballs manufactured at this facility included the figure-eight and lemon-peel designs. To supply leather for production, a special tannery was built by Harwood just east of Sawin Street at the "Tannery Pond." Eventually, the pond—many nearby residents called “Stink Pond”—became such a blight that the tannery was shut down.

Harwood’s “League Balls” were sold nationwide and in Canada. By 1870, the factory routinely filled single orders for up to 6,000 balls from its best customers. The New York Times reported that Harwood & Sons was “the greatest base ball manufactory in the world.” More than 200 women were employed doing piecework in the factory building. Over the years, innovative machinery was designed to take over much of the manual work. Of course, many competitors nationwide got into the baseball-making business as the decades passed.

Three generations of the Harwood family continued making baseballs in Natick. The Harwood operation in Natick closed in 1976, and the building that had housed America’s first baseball factory was converted to condominiums and commercial space by 1988. It is still in use at 12 Walnut Street, bearing a plaque that marks its place in town and baseball history.

Selected sources and additional reading:

Natick Historical Society collections.

Hample, Zack. The Baseball: Stunts, Scandals, and Secrets Beneath the Stitches. New York: Anchor Books, 2011.